Engineering and technological services

Every project is a new challenge and we take the most care to every single detail, without ever losing the complete picture. We believe that every machine should be seen as a system and that every system is a part of a plant. With this belief in mind and with an expertise that comes from 40 years of installations worldwide, we have earned the trust of leading ceramic industry players.

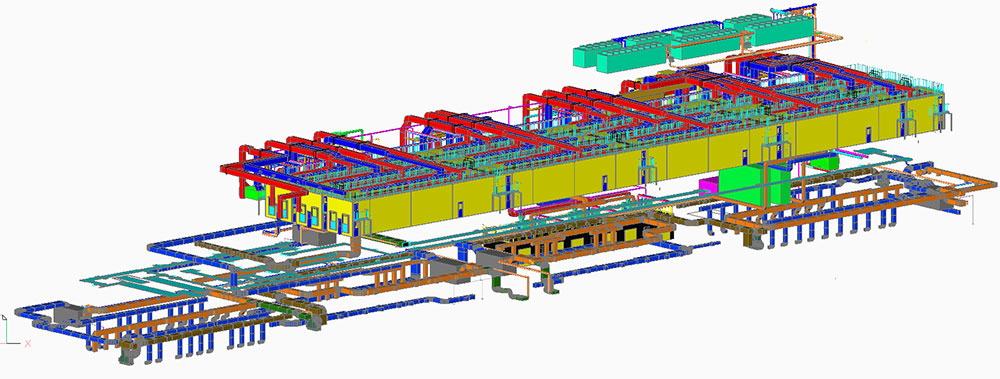

We design factories that ensure highly efficient production flows, optimisation of space, safety and well-being for workers and, of course, the best solutions for energy consumption.

We provide:

Progetti Lab: from ideas to measurable results

Our team of engineers takes advantage of discussions with expert technologists in the field to learn more about thermodynamics processes; we collaborate with Universities, such as Politecnico di Milano, with which we have developed theoretical studies on air distribution. We constantly aim at the development of new technologies and we always test our ideas to get the best drying/curing curve and to design tailor-made solutions.

Customer training is also an important part of our philosophy. From standard manufacturing processes to the latest available technologies, we help client’s personnel to upgrade their skills and improve production performance.

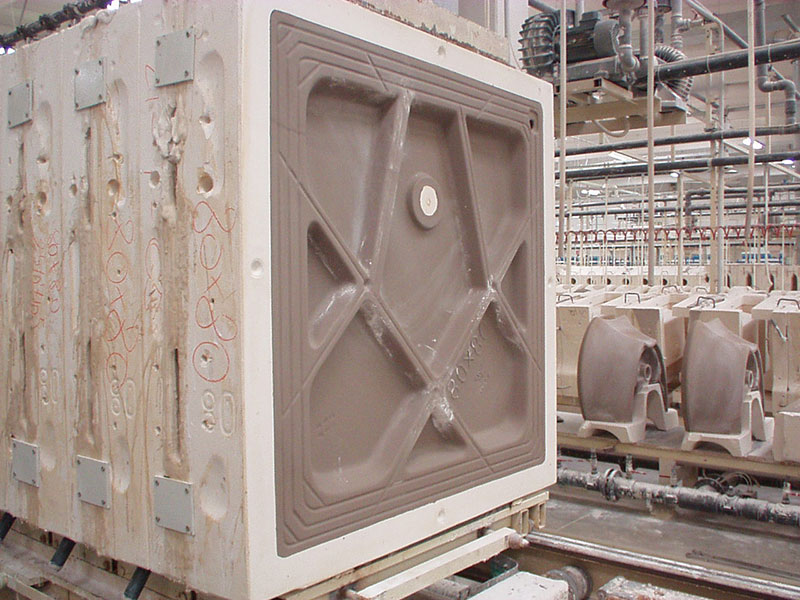

Technological support for slip and mould development

Thanks to a team of experts with an extensive know how, we support development or improvement of ceramic recipes to reach higher yield and quality standards, starting from customer-supplied raw materials or by sourcing new ones. In addition, we provide advice for making plaster moulds in order to improve their physical properties, optimize the casting rate, and obtain the desired thickness of the green cast body.

Drying Tests

Our approach to drying is scientific and accurate. Nothing is left to chance and no processes are random. Our dryers for tests and kilns for laboratories are designed for customer products and typical ceramic drying process. This way our technical team runs specific drying tests to find the best drying cycles for each product.

Progetti dryers for testing can be rented by customers, as they are easily transportable by truck or container and complete with all the necessary laboratory probes and specific tools.